Air Inlets

A critical time for ventilation of livestock structures is during cold periods, when it is necessary to ventilate the structures to supply fresh air to the animals without causing cold drafts over them, a process commonly known as minimum ventilation. The only way of performing minimum ventilation effectively is by directing the cold fresh air along the ceiling of the structure so that it can mix thoroughly with the hot air inside the structure before it descends into the occupied zone of the animals and replaces the stale air. Failure to perform minimum ventilation effectively could cause a build-up of noxious gases, such as ammonia or carbon dioxide, inside the structure; or, a fatal reduction in oxygen levels.

Another problem commonly associated with ineffective minimum ventilation is cold air dropping onto the animals, causing wet litter and disturbing animal behaviour. The air inlets are designed to perform minimum ventilation perfectly; maintaining a healthy environment for the animal without disrupting normal animal behaviour.

During warmer periods the emphasis of ventilation shifts towards heat removal and cooling of the animals. In such conditions the air entering the structure can be directed downwards towards the animals, allowing heat removal from the animals skins through a wind chill process. Once again the inlet can be adjusted to ensure that the air reaches the animal.

Agromax offers several models of air inlets

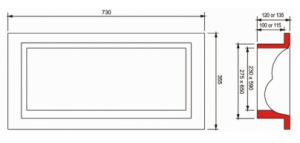

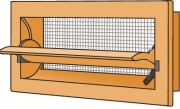

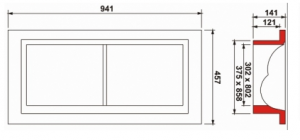

Model AI3000

Air inlet, made of high quality polyurethane. Flangsmodel with flange on the frontside. Capacity in m3 10 Pa = 2950

.jpg)