Cockerel feeding system

In the current competitive poultry industry, every poultry grower is looking to increase his production efficiency. The Agromax Pan Feeding System helps to achieve excellent feed conversion, has reliable operation and ensures more profits with its many advantages.

• Grill-less pan: it allows the birds to easily reach the feed during the first days (a feed level adjuster which also divides the feed pan in compartments) |

|

• Adequate feed level and easy access ensures enough feed for starting baby chicks and ability to adjust the pan to low feed level later to avoid wasting feed as the birds grow.

• The deep ‘V’ shaped pan bottom allows feed to be reached easily by birds while maintaining a low feed level.

• A fast distribution of fresh feed (350 kg/hour) over the entire line ensures uniform growth for all birds.

• The pan has different settings to choose your desired feed level with just a simple twist and makes feed management easier and ensures only fresh feed is available to the birds.

• The feeder pan is made of high quality synthetic material which is very UV resistant. And also resistant to all disinfectants and cleaning products used on farms, giving a long and trouble-free life.

• The pan is easy to mount, dismount and clean.

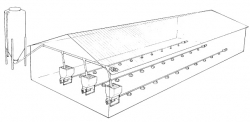

System calculation

Number of birds per pan: Moderate climate: 80 broilers per pan

Hot climate: 65 broilers per pan

Number of feeder lines per house <=12m 2

12 up to 15 m 3

for every 3m wider add one extra line

How to calculate the cost of your pan feeding system :

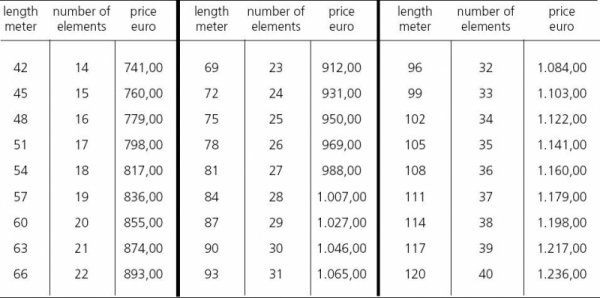

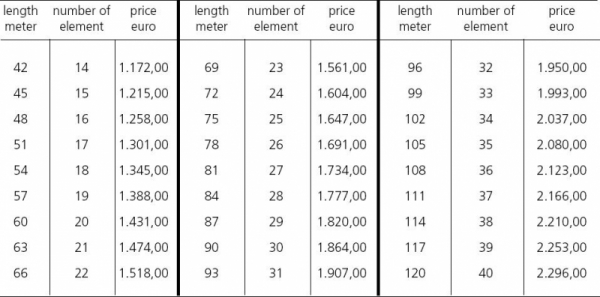

In the table below you find the cost of complete pan feeder lines consisting of: hopper, drive unit, 3 meter element of each galvanised tube of 3 meter, one piece tube coupler and 3 meter spiral, without pan and suspension material, just add the price and number of feeder pan per element ( 1, 2, 3 or 4 pan ) to get price for the complete line with pan.

For suspension material : per line you need 1 basic set of 1 winch and 2 corner pulleys (cost per set 60 euro) then per set for each element of 3 meter: 1 pcs. 45 mm. pulley, 3 mtr. 5 mm cable, 1 pcs. cable clamb and 4 mtr. hanging rope (price per set 60 euro).

System calculation example

A broiler house (in the Netherlands) size 18 mtr X 98 mtr. with density of 20 broiler/square meter so total 1764 square meter for 35.000 broiler. Around 70 broiler/feeder pan so 500 pan and 4 lines needed each 93 meter. 31 elements each with 4 pans makes a total off 496 pans.

Price per line …. so for 4 lines …. with M3 pan / 496 pan per 8 euro / pan is 3968.

The costs for the complete feeding system with pan are….

For suspension material basic set for the 31 elements x 4 lines is 124 elements by 4.5 / set makes a total…

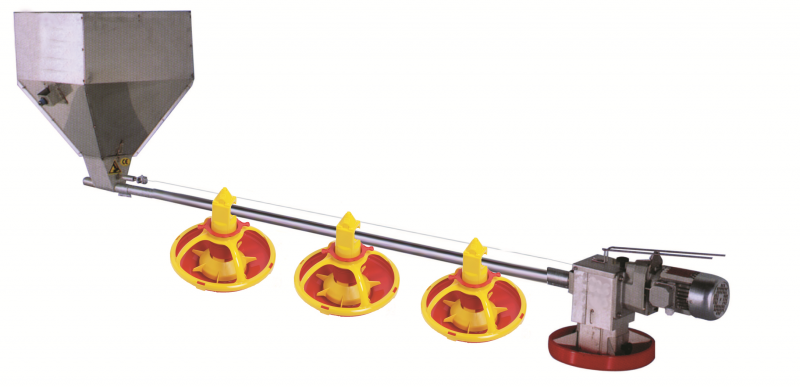

Cockerel feeding system

The advantages of separate feeding of female and male breeders are widely acknowledged.

Providing separate feed rations for cockerel is extremely important to:

Maintain proper body weight while reducing foot and leg problems.

Increase fertility & hatchability.

Eliminate need to spike the flock with new males which also decreases disease introduction.

Motivate cockerel towards prescribed duties.

The feeding system features

Fast and uniform filling of all pans.

Optimal feeding space thanks to open pan.

Feed level easy and with precision adjustable with special design of pan to prevent feed wastage.

Non swinging pan, very strong an stable.

These combine to reduce feed consumption and maximize fertile egg production.

We recommend 1 pan per 7 cocks

Price calculation: see same way like broiler pan feeding system

In the table below you find the cost of complete feeder line with 4 pan per element consist of: hopper, drive unit, 3 meter element of each galvanised tube of 3 meter, one piece tube clamp and 3 meter spiral, complete with suspension material (based in ceiling hand winch, pullies, cables, ...).