Type of Company

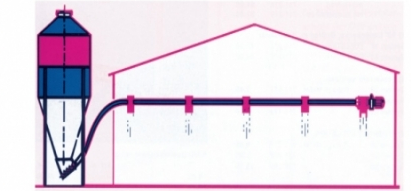

Flex auger filling system

|

Agromax flex auger systems have proven to be very reliable for transportation of the feed from silo’s to feederlines in both new and

existing buildings. The design of the system enables flexible

installation with the use of 45º bends.

The drive unit consists of a frame with a direct drive flange gearbox

motor with motor protection switch, Test level sensor and end-outlet.

The overload-switch protects the flex auger from damage in case of

blocking.

The loading hopper/silo-boot, available in horizontal and 30º sloping models, is designed for easy operation and durability.

Both, the single and double are provided standard with an inspection

window, shaft and ball-bearing. Diam. 440/530 mm.As an option the

silo-boots can be supplied with shut off valves.

Supplied in 2 versions - Metal boot - Plastic/metal boot Loading hopper in black or transparent |

|

The low noise level of the special steel auger in the p.v.c. tube makes it the

ideal system for feed transport in any livestock building. The tubes are

produced with a glare-fitting to facilitate the connection of the tube and to

assure proper sealing, which makes the system also suitable for outdoor use.

The intermediate outlets, made of p.v.c. and provided with an opening/closing

slide, can be located at any position along the flex auger system.

Electrical valve for feed dosing

|

|

System calculation

Flex - auger Model 75 Feed transportation system delivers 1300 kg/h

Flex - auger Model 90 Feed transportation system delivers 2600 kg/h

Flex - auger Model 90 High capacity Feed transportation system delivers 3900 kg/h

Flex - auger Model 125 Feed transportation system delivers 6000 kg/h